Jumbo unloading system tend to be more Charge-successful than 250 kilograms to 1000kg bags. This is a swift, clean, and economical technique for emptying bulk and semi-bulk baggage of their complete contents, especially when the material just isn't wholly totally free-subsequent

Every passage is often controlled by a PLC panel, which ensures tailored parameter configuration, based upon the precise properties of each product.

Bag sizing and weight: Jumbo bag filling machines can cope with baggage of different sizes and weights, so it’s crucial to pick a machine which will accommodate the bags you'll be making use of.

Redline Systems is situated in Clearfield, Utah and is in operation for over 40 decades. Redline Systems specializes in setting up excellent conveyors for every type of apps.

In many factories, guide weigh batching is time-consuming and susceptible to mistakes. Automatic batch weighing and Manage systems using load cells improve efficiency by automating this method. Regardless of whether in meals processing, prescription drugs, or chemical output, load cells be certain Each and every batch fulfills demanding weight specifications, retaining regularity and high quality.

The vacuum siphon is set in the significantly edge of the line to supply the sights to pull material commencing with 1 place then onto the subsequent. The adverse weight during the framework is constrained by a vacuum help valve to ensure the best measure of material comes at its goal or a lot of locations.

This automatic bagger may be the quickest tabletop poly mailer packaging system on the market for mail get fulfillment packaging.

Dependant upon the gas velocity as well as the material features, a variety of circulation-designs can be observed, as revealed in Determine one. At a relentless solids feed amount, because the gasoline velocity improves, the packed mattress will completely transform into a going slug movement, that can then degenerate into dunes or unstable more info dunes, after which you can eventually the particles will completely entrain in to the gasoline stream resulting in homogeneous flow.

Facilitating Risk-free and successful consumer operation, and enabling productive inputting of products to the process stream are efficiency benefits engineered into every single NBE bag crack station hopper grate. Bolt-in Hopper Grate

COMPONENTER® batching equipment from AZO provides a remarkably exact, automated dosing and weighing system for minimal and micro-substances. The system is as versatile because it is robust, enabling for exceptional answers that could be utilised in a variety of industries.

Any time you get, lease, or lease from Harmony Enterprises, we employ our Established System to provide you with the industry’s most impressive solutions, a real partnership, plus the widest variety of recycling and waste solutions available in the marketplace today.

For NBE bag split stations ducted into a central dust assortment system, this non-sealed edge hood-and-door style offers protection of the material enter spot and hopper from ambient dusts and other contaminants. Glove Box Material Containment Enclosure

Concetti generates systems for different production requires, based on the consumer's requirements. Here i will discuss the solutions:

You may think this would be a really perfect operating problem, but It's not at all. The flow hydrodynamics at the utmost carrying potential corresponds on the saltation flow, which happens to be the point at which, if the gasoline velocity decreases, particles will fall (or salt) out in the circulation stream. At this point move is unstable, and running at or in the vicinity of this position inside a business system is demanding. Dilute phase systems are style and design to function at fuel velocities marginally previously mentioned the saltation velocity. Dense phase systems operate underneath this issue.

Jaleel White Then & Now!

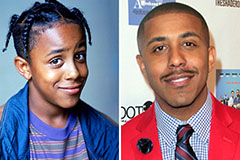

Jaleel White Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!